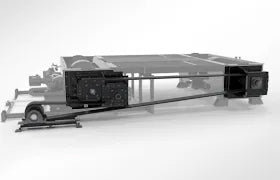

424 LINX SYSTEM

Mechanically links 424x or 424xLC2 dynos to eliminate potential speed differentials between dyno rollers.

Single Phase electrical supply:

Mechanically links 424x or 424xLC2 dynos to eliminate potential speed differentials between dyno rollers.

Add to an existing model 224x or 224xLC to gain four wheel drive testing capability. Available for pit or above ground installation. Can accommodate 88” to 130” wheelbase (Optional 98” to 140”).

The training that comes included for Dynojet Dynamometer owners classifies you as a “Dynojet Approved Car Dyno Center” The certification course is a done at your location, ensuring you know how to fully operate your dyno in your own surroundings. Upon completion, you will become a "Dynojet Approved Dyno Centre" and will be listed online, so that potential customer can easily find you through our Dyno Centre search tool.

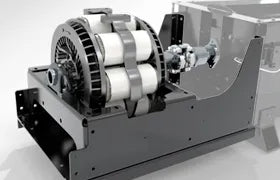

Eddy current absorption unit and all necessary hardware to attach to roller. Perform loaded tests, including step, sweep, and closed loop. (pit or above ground)

Measures real-time air/fuel ratios with integrated high-flow “pump” inside dyno (requires shop air).

Includes one wideband O2 sensor with harness for use with AFR-2 for dual air/fuel readings. Available in a 6ft or 12 ft harness length.

Analog Channel Accessories Analog Sensor Cable Kit (Used for connecting customer supplied 0-5v sensors to DynoWare RT Main Control Module – includes 4 harness kits).

Optional Harnesses:

Includes professional grade Riv-Nut tool, drill bit, and enough hardware for 50 applications (Includes bolts, washers, Riv-Nuts, specialty bolts, and billet manifold interfaces.)

Includes drill bit, bolts, washers, Riv-Nuts, specialty bolts, and billet manifold interfaces.

Measures real-time torque, and allows sweep, step and custom load simulation tests.

Includes 10-500f sensor, magnetic base and mounting stand.

Includes magnetic base, optical sensor and reflective tape. Recommended when testing diesel engine vehicles. Can also be used for other purposes such as measuring pulley slip.

Receive RPM signal by plugging into cigarette/accessory power port or connect to positive/negative battery posts for RPM signal.

Necessary when using the four-post lift. Consists of a platform for the rear of the dyno with a lift interface kit.

Required when installing the dynamometer into a pit/in-ground installation. Covers open areas exposing the dyno roller only.